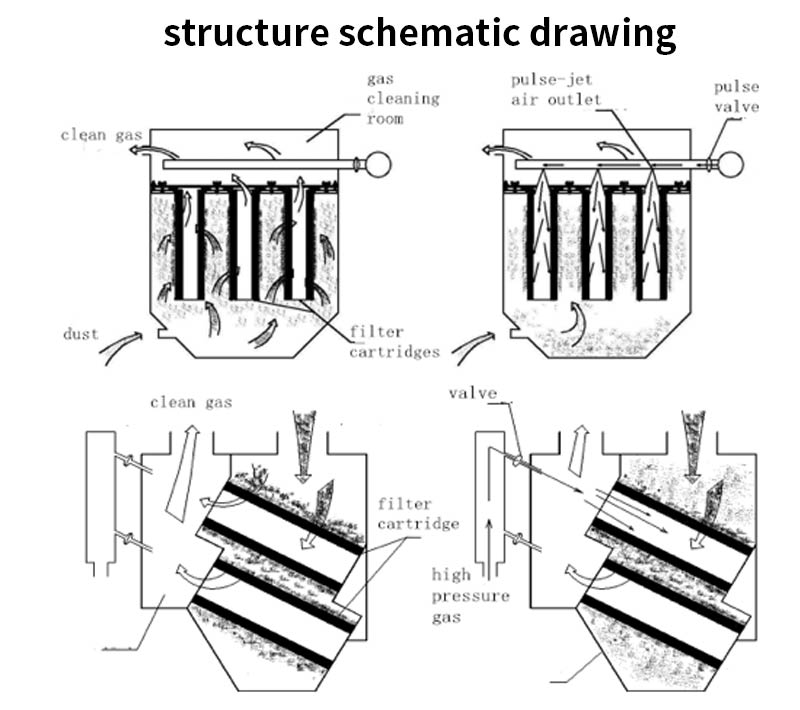

1.Layout of filter cartridges in dust collectors

Generally, there are two main installation ways of filter cartridges in dust collectors that conclude inclined (horizontal) layout and vertical layout. It is convenient to assemble and disassemble filter cartridges in inclined (horizontal) layout, and it is better to use inclined (horizontal) layout in low dust concentration occasion. Also, while vertical layout, the cartridges can be installed from the top or the bottom. While installing from the top, filter cartridges are above the tubesheet and inserted into the tubesheet pore downward,then fixed on the tubesheet; on the other hand, while installing from the bottom, filter cartridges are under the tubesheet and installed upward, then fixed on the tubesheet. It is convenient to assemble and disassemble filter cartridges while installing from the top because it is unnecessary for operation staffs to go into the box of the dust collectors for operation; on the contrary, it is difficult for operation staffs to assemble and disassemble filter cartridges while installing from the bottom because they have to go into the box with poor working condition to operate. It is more suitable for high dust concentration occasion to use vertical layout of filter cartridges. Pulse-jet dust cleaning effect for vertical layout of filter cartridges is better than inclined (horizontal) layout when dust concentration occasion is high.

2.Choice of Filter Media

1.Before choosing filter media, it is necessary to think about whether the dust is flammable or not. If it is flammable,we suggest to use anti-static filter media or taking other measures to prevent static flash over generating explosion.

2.As human’s environmentally friendly consciousness growing, dust emission restriction is more and more strict, especially for heavy metal, silicon dioxide, and so on;which damages the human health seriously. Therefore, surface filtration type filter media must be chosen, a kind of filter media with hyper-fine fiber laminated on the surface has advantages as below: high filtration precision, easy for dust-cleaning, low resistance, stable operation, etc.

3.If the working condition is high humidity, dust absorbs moisture easily or dust with oily components, it is recommended to choose filter media that function oil, water, and dirt repellent.

4.If sparks in the system, flame retardant filter media should be used to avoid burning in the filter cartridges (cautious on welding fume treatment).

5.If the dust concentration of dust collectors is very low (such as atmospheric dusting, welding flume, etc.), it is suggested to choose ≤180 g/㎡ thin filter media because it is helpful to increase filter area and flow rate of a single filter cartridge.

6.Working temperature: the working temperature of filter media with main element is polyester materials, is ≤135℃. When polyester nonwoven fabrics are used between 80℃-135℃, the stiffness of fabrics would drop significantly; which makes pleated filter media to stick together easily. In this case, we would adapt some special measures to make the filter media being pleated evenly, and keeping good air permeability.

3.Choice of filtration area of filter cartridges

1.The definition of filtration area is the very area of the completely-spreaded filter media. The longer a filter cartridge is , the less cost it will be, when the filter cartridges are vertical layout . However, it will be hard to remove dust if the filter cartridge is too long. Currently, the longest filter cartridge in the world is 2 meters, and our company is capable for manufacturing it.

2.The higher dust concentration of the inlet of dust collectors is, the less pleats and lower pleat height should be made for filter media which means less filtration area and it is helpful to remove dust in dust collectors.

4.Choice of filtration wind

The definition of filtration wind is a ratio between the volume of filtration dust and filtration area in a time unit . In general, the filtration wind of a filter cartridge is 0.6-1.2m/min and the ideal wind is around 0.8m/min. In case of higher dust concentration, lower filtration wind should be considered, lower wind helps to increase filtration efficiency of dust collectors, extend service life of filter cartridges, reduce working resistance, and improve ventilation property. Meanwhile, the cost of producing dust collectors will be increased. In some special situations, wind of filter can be up to 2m/min.

5.Influence of Venturi tube to dust removal property of filter cartridges

If Venturi tubes are installed in dust cleaning system while pulse-jet, blowing airflow goes into Venturi tubes, and the airflow speeds up as the venturi cross section shrinks. The faster air flow is , the lower pressure is; and it forms a negative-pressure zone and sucks the air in which creates the second airflow. It will greatly increase blowing air volume. When air goes into filter cartridges through Venturi tubes, pressures are well distributed inside the filter cartridges. It greatly improves dust-cleaning effects and reduces air consumption.

6.Localization of filter cartridges and filter media

Filter cartridges have been used in developed countries since 1970s, it is greatly developed so far, it has been using for long time with the imported equipment in China. After mid 1990s, we could only produce some low-end cartridges with imported normal polyester spunbonded media (not surface filtration media). Along with development of Chinese nonwoven industry, it makes the Chinese made filter cartridges and media much possible. The development of domestic nonwoven industry creates the condition for domestic made filter cartridges and media. In 2000s, we further invested in developing surface filtration media. N (nano-fiber) through electrospinning and PTFE hot melt lamination (F4) of surface filter media have been successfully developed so far. Especially in N types, they have lower price, higher filtration precision, easier cleaning methods ,and lower operating resistance, etc.